What are Engineering Controls?

Engineering Controls isolate the employee from exposure to BBP and hazardous materials by physically changing an environment or instrument. Engineering controls must be replaced regularly to ensure effectiveness, and always be maintained and examined properly.

A few examples can include:

- Bench top splashguards

- Needle safety devices

- Biological safety cabinets

- Blood and capillary tubes

- Personal protective equipment

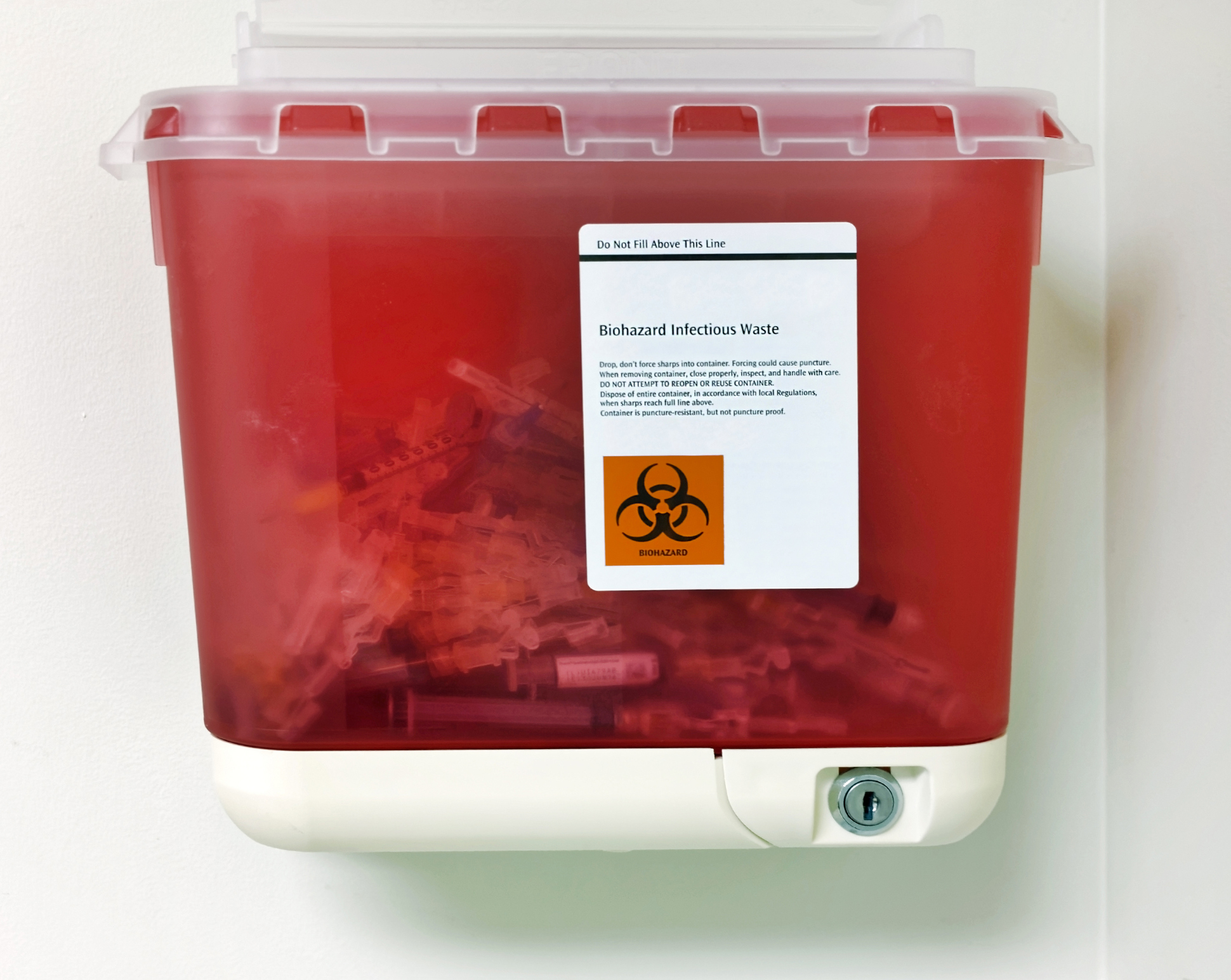

- Sharps/waste disposal containers

- Biohazard symbols, brooms/mops, safety cones and other pertinent safety equipment

Containment equipment

Containment equipment can include but is not limited to:

- Biological safety cabinets

- Animal cages

- Laboratory decontamination

- Plant survival systems

- Centrifuge containers

What are a few examples?

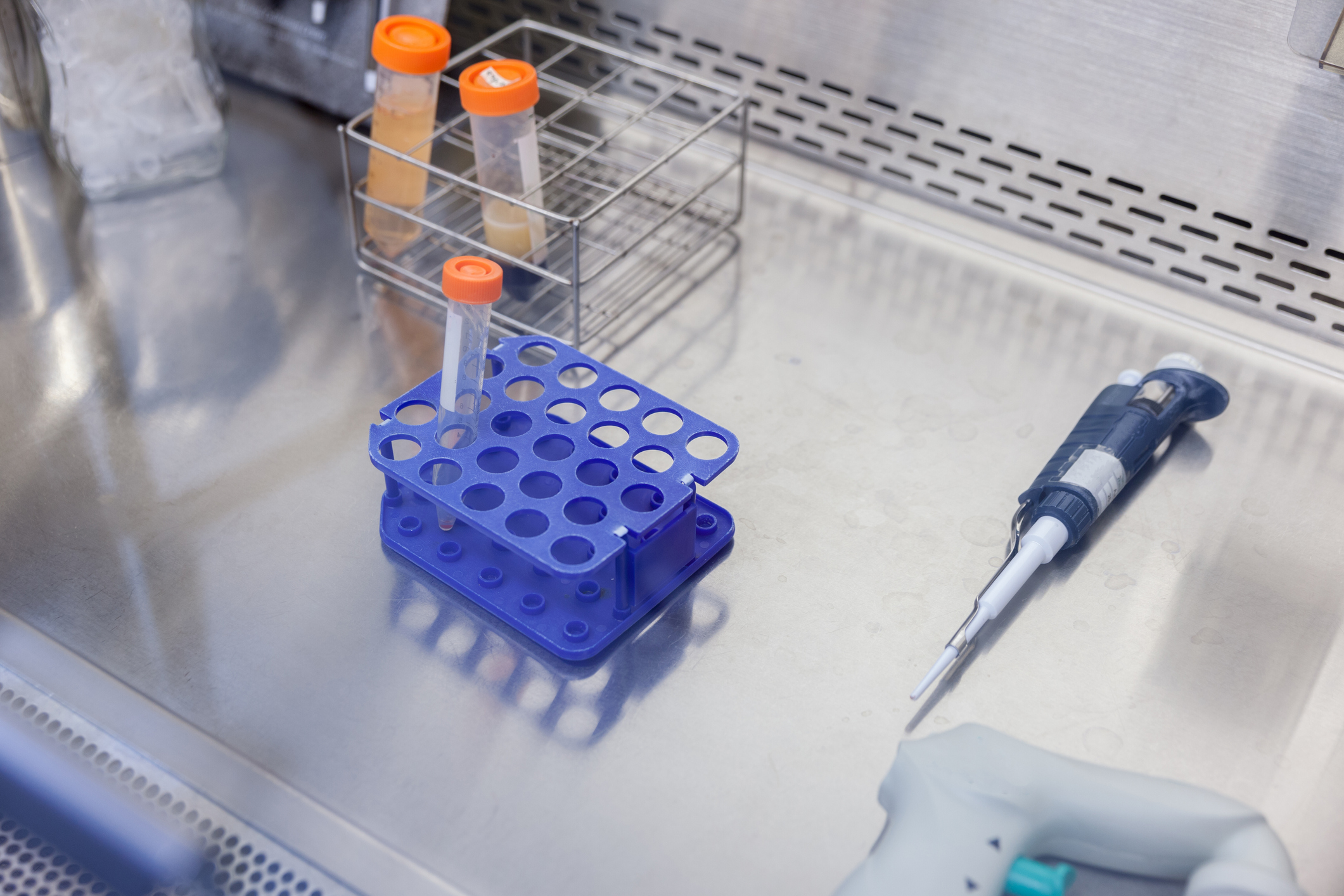

Biological safety cabinets (BSC) are enclosed, ventilated laboratory workspaces dedicated to safely working with materials contaminated with BSAT (Biological Select Agents and Toxins).

Alkaline hydrolysis digesters, pathological incinerators, or other approved means, should be provided for the safe disposal of the large carcasses of infected animals. Redundancy and the use of multiple technologies need to be evaluated and considered.

An Effluent Decontamination System (EDS) is a system that sterilizes biohazardous liquid waste generated from biocontainment laboratories or other facilities prior to discharge. Building ventilation and exhaust or HVAC must provide safe, breathable and comfortable environments for all employees and the public, and to minimize exposure to hazardous air contaminants. At BSL-3 and BSL-4, exhaust laboratory air must be directly exhausted to the outside since it is considered potentially contaminated.

High-Efficiency Particulate Air (HEPA)-filters can be used to exhaust room air in order to stop hazards from being released to the outside environment. The HVAC exhaust system must be sized to handle both the room exhaust and the exhaust requirements of all containment devices that may be present. Adequate supply air must be provided to ensure proper functionality of the exhaust system.

Additional containment of BBP

Additional containment involves the protection of the environment external to the workshop and clinical laboratory from exposure to potentially infectious materials. It is provided by a combination of efficient facility design and proper operational practices.

Secondary containment may include:

- Separation of the laboratory work area from areas of public access.

- Availability of decontamination equipment, such as separate dirty and clean corridors, autoclave, washing facilities, double entryways, etc.

How to enclose and isolate BBP

Common isolation techniques are utilized to create a contaminant-free area either around the equipment or around employee workstations. Isolation places the hazardous process far away from most of the workers, while an enclosure keeps a selected hazard physically separated from workers.

Enclosed equipment, for example, is tightly sealed and it is typically only opened for moving samples and cultures or for cleaning and maintenance. Care must be taken when the enclosure is opened for maintenance as exposure could occur if proper precautions are not taken. The enclosure itself must be well maintained to prevent leaks.

What are Work Practice Controls?

Work Practice Controls are how tasks can be performed to reduce risk and exposure to BBP or OPIM.

Prohibited practices include:

- Cosmetic application

- Handling of contact lenses

- Drinking, eating, or smoking

- Food and beverages near or in contact with OPIM or blood

- Recapping, breaking or bending needles

- Mouth pipetting

Other Work Practice Controls include restricting workshop or clinical laboratory access to employees with permission. Workshop or clinical laboratory personnel should frequently cleanse their hands with soap and water in respective hand washing facilities and use a no-hands procedure when disposing of contaminated objects.